Aerospace IT Compliance: How To Prevent AS9100 Audit Failures From Legacy Systems

Aerospace IT compliance presents unprecedented challenges in an industry where a single aircraft fuselage may involve parts from 480 different suppliers and 2,000 additional sub-suppliers. While major manufacturers meticulously track 14,000 critical features during production, the complexity of maintaining regulatory adherence has never been greater. This intricate supply chain ecosystem demands robust quality management systems that can withstand rigorous AS9100 audits.

The consequences of compliance failures in aerospace manufacturing are severe. A single violation can cost companies millions in fines and lost business opportunities, crippling cash flows and damaging reputations. Additionally, organizations face significant staffing challenges, with 89% of large businesses concerned about IT personnel shortages for maintaining legacy systems. More concerning still, companies report losing an average of 23% of specialized mainframe staff over five years, with 63% of these critical positions remaining unfilled.

These challenges highlight why outdated legacy systems pose substantial risks to aerospace compliance standards. Systems lacking automation, traceability, and integration capabilities create significant vulnerabilities during AS9100 audits. This article examines how aerospace manufacturers can identify legacy system risks, understand their impact on compliance requirements, and implement modernization strategies to ensure audit readiness in an increasingly complex regulatory landscape.

Key Takeaways

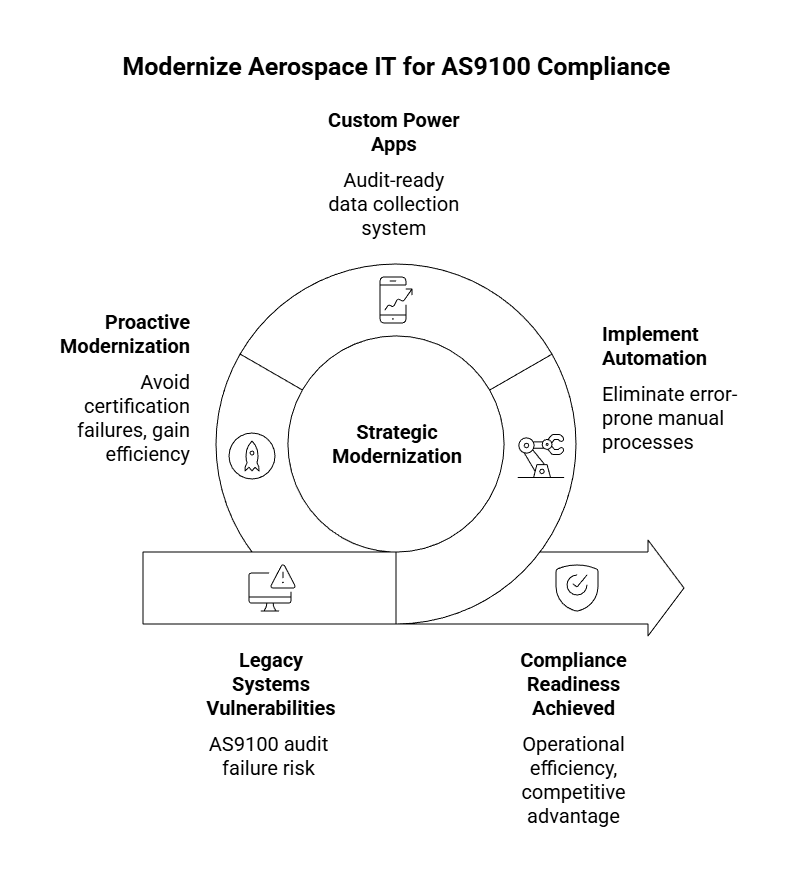

Legacy systems in aerospace manufacturing create critical vulnerabilities that can lead to costly AS9100 audit failures, but strategic modernization offers clear solutions to ensure compliance readiness.

- Legacy systems directly violate AS9100 requirements – Outdated IT infrastructure fails operational risk management (Clause 8.1.1), traceability mandates, and non-conformance detection capabilities essential for certification.

- Talent crisis amplifies compliance risks – 89% of aerospace companies face IT staff shortages for legacy systems, with 63% of specialized mainframe positions remaining unfilled as experienced developers retire.

- Security vulnerabilities threaten operations – Aviation ransomware attacks increased 600% between 2024-2025, while legacy systems lack essential security features like multi-factor authentication and encrypted backups.

- Modern automation prevents audit failures – Power Automate workflows eliminate error-prone manual processes, while custom Power Apps and Microsoft Dataverse provide audit-ready data collection and comprehensive compliance tracking.

- Proactive modernization delivers competitive advantage – Companies that address IT compliance gaps avoid costly certification failures while gaining operational efficiency benefits that outweigh modernization investments.

The aerospace industry faces a critical decision point: continue risking audit failures with obsolete systems or invest in proven modernization strategies that ensure AS9100 compliance and operational excellence.

Legacy System Risks in AS9100 Audit Context

Legacy systems in aerospace manufacturing create significant compliance vulnerabilities during AS9100 audits. These outdated technologies, often running critical operations, introduce multiple points of failure that can derail certification efforts and compromise quality management systems.

COBOL and Assembler Dependency in Aerospace IT

The talent crisis surrounding legacy programming languages poses a fundamental threat to aerospace compliance. A staggering 89% of large businesses express concerns about IT staff shortages for maintaining legacy systems, with organizations losing an average of 23% of specialized mainframe staff over five-year periods. More concerning, 63% of these crucial positions remain unfilled.

COBOL remains prominent in 75% of mainframe environments, yet qualified developers have become extraordinarily scarce. Similarly, Assembler—used by 66% of large enterprises—faces comparable talent drought. Other critical languages in aerospace systems include CA Gen (37% of organizations), CA Telon (24%), and PL/1 (15%).

As one industry expert notes, “The mainframe had its heyday in the 70s, 80s and 90s… we are now 40 years on, these people are at the end of their careers and about to move into retirement, yet for the last 30 years there has been no new talent coming through the funnel to replace them”.

Manual Process Failures in Audit Documentation

Legacy systems force aerospace companies into risky manual workarounds that undermine audit readiness. These manual processes for documentation, audits, and reporting are “not only inefficient and time-consuming but also prone to human error”.

Engineers hired to perform certification testing often “spend a significant amount of their time acting as librarians” instead of focusing on core tasks. Paper-based tracking systems introduce multiple pain points including transcription errors, misplaced records, and audit delays.

Data Visibility Issues in Legacy Reporting Systems

Most aerospace manufacturers still rely on outdated platforms that trap critical data in silos such as spreadsheets, isolated quality modules, or unsupported software. This visibility gap creates significant compliance risks, particularly when attempting to demonstrate process controls during audits.

Without real-time data transparency, teams depend on outdated reports or email updates to track supplier performance, shipments, and production timelines. Consequently, aerospace mainframe systems struggle to satisfy AS9100D Clause 8.1.1, which mandates structured processes for operational risk management, including “assignment of responsibilities” and “definition of risk assessment criteria”.

Furthermore, rigid mainframe architectures typically prevent real-time risk assessment and communication across the five critical functional areas: Program Management, Sales/Contracts, Design and Development, Purchasing, and Production and Service Provision.

How Legacy Systems Violate AS9100 Requirements

Specific compliance failures emerge whenever aerospace companies attempt to maintain AS9100 certification with obsolete IT infrastructure. These technical deficiencies create direct violations of critical standard requirements across multiple clauses.

Clause 8.1.1: Operational Risk Management Gaps

Aerospace mainframe legacy systems fundamentally struggle to satisfy AS9100D Clause 8.1.1, which mandates structured processes for operational risk management. This clause requires “assignment of responsibilities for operational risk management” along with “definition of risk assessment criteria”. Unfortunately, rigid mainframe architectures typically prevent real-time risk assessment and communication across the five critical functional areas: Program Management, Sales/Contracts, Design and Development, Purchasing, and Production and Service Provision.

The scope of Clause 8.1.1 specifically applies to risks introduced to the organization from each functional business area. However, legacy systems often lack the flexibility to implement these requirements effectively. Although legacy systems might handle basic operations, they rarely provide the dynamic risk management capabilities needed for modern aerospace certification.

AS9100 Traceability Requirements and System Limitations

Traceability represents another critical compliance area where legacy systems create direct violations. AS9100 Rev D includes five specific requirements for identification and traceability in clause 8.5.2. These include maintaining suitable identification, configuration management, status identification, controlled acceptance media, and comprehensive traceability.

Legacy systems generally cannot handle essential aspects like bill of materials traceability or audit trails. This limitation forces aerospace manufacturers to rely on spreadsheets, emails, and other workarounds. In fact, 48% of workers waste three hours or more per day due to inefficient legacy systems, costing the average business at least $37,000 annually in lost productivity.

Non-conformance Detection Failures in Manual Workflows

AS9100D requires organizations to detect non-conformities through inspections, audits, or real-time monitoring systems. Subsequently, organizations must react to non-conformities, determine root causes, implement corrective actions, and maintain documented evidence.

Legacy systems force aerospace companies into risky manual workarounds for activities like documentation and audits that are “not only inefficient and time-consuming but also prone to human error”. Engineers hired to perform certification testing often “spend a significant amount of their time acting as a librarian”. This non-value-added work diverts resources from innovation and creates dangerous compliance gaps that ultimately threaten regulatory standing.

System Integration and Security Gaps in Legacy IT

Outdated aerospace IT environments create profound integration obstacles that compromise AS9100 compliance capabilities. These deficiencies extend beyond basic functionality issues, threatening audit readiness across multiple domains.

Integration Failures with Modern ERP and QMS Tools

Legacy aerospace systems frequently lack connectivity with modern platforms, forcing teams to duplicate data entry across disconnected systems. This disconnection creates significant compliance vulnerabilities as teams juggle multiple tools rather than making unified updates. According to Aberdeen Group, legacy ERP systems deliver correct data only 30% of the time or less, undermining compliance activities that depend on accurate information.

Unsupported Software and Patch Management Risks

Aerospace systems running unsupported software face heightened security threats. Between January 2024 and April 2025, the aviation industry experienced a 600% increase in ransomware attacks, with 27 major incidents tied to 22 different groups. These legacy tools typically lack essential security features including multi-factor authentication or encrypted backups. Furthermore, in the first half of 2023, the rate of unfixed industrial control system flaws rose dramatically from 13% to approximately 34%.

Vendor Lock-in and Compliance Inflexibility

Proprietary aerospace systems deliberately “shackle contractors to the past” through vendor lock-in strategies. Vendors strategically leverage proprietary APIs and data formats to “muscle out competition and lock clients into their ecosystem”. This inflexibility creates what experts term “data imprisonment”, restricting access to siloed data sets essential for audit activities. Eventually, these limitations prevent organizations from implementing necessary compliance-focused upgrades.

Modernization Strategies to Prevent Audit Failures

Modern digital tools offer aerospace manufacturers practical solutions to prevent AS9100 audit failures. Companies can implement these technologies to transform legacy processes into audit-ready systems.

Using Power Automate for AS9100 Workflow Automation

Power Automate enables aerospace manufacturers to create automated workflows that send audit reminders to concerned personnel. These workflows ensure follow-up actions are completed efficiently throughout the audit process. Most importantly, automation eliminates the manual documentation processes that frequently result in compliance gaps. Aerospace companies can establish automated compliance tracking and reporting systems that maintain continuous adherence to AS9100 requirements.

Custom Power Apps for Audit-Ready Data Collection

Custom Power Apps provide remarkable advantages for aerospace audit data collection. These applications run on tablets or phones, delivering optimal user experience even without internet connection. Cosimo Grassi’s custom Audit History Manager demonstrates how Power Apps can transform auditing with advanced filtering by entity, record GUID, field, user, date, and action. Such applications allow for expandable audit records, detailed change tracking, and streamlined data retrieval—essential capabilities for AS9100 compliance.

System Integration for Compliance with Microsoft Dataverse

Microsoft Dataverse offers comprehensive auditing features specifically designed to meet stringent compliance requirements. The platform logs changes to customer records in an environment with a Dataverse database. These audit logs help administrators answer critical questions: who created or updated records, which fields changed, what were previous values, and who accessed systems.

Real-Time Dashboards for QMS Audit Readiness

Real-time dashboards present consolidated audit metrics, enabling aerospace quality teams to maintain continuous audit readiness. Microsoft Purview supports detailed auditing across Power Platform, including Copilot Studio events, to meet compliance requirements. Dataverse audit capabilities in the Power Platform admin center provide comprehensive logging of admin, maker, and user activities—identifying potential security threats before they escalate. By customizing Dataverse audits for various entities and fields, aerospace manufacturers gain visibility into data interactions, maintaining secure, compliant environments.

Conclusion

Legacy systems represent a critical threat to aerospace manufacturers seeking AS9100 certification. Throughout this analysis, we have seen how outdated IT infrastructure creates direct compliance violations across multiple clauses. Particularly, these systems fail to support operational risk management requirements under Clause 8.1.1, while simultaneously compromising traceability mandates and non-conformance detection capabilities.

Additionally, the talent crisis surrounding legacy programming languages compounds these challenges. Organizations facing the retirement of specialized mainframe staff without adequate replacements find themselves increasingly vulnerable during audits. Therefore, aerospace manufacturers must acknowledge these risks before they escalate into certification failures with severe financial and reputational consequences.

Security vulnerabilities present another significant concern. The dramatic 600% increase in ransomware attacks against aviation entities between January 2024 and April 2025 underscores this threat. Subsequently, organizations running unsupported software face heightened exposure due to unpatched vulnerabilities and inadequate security features.

Fortunately, practical modernization pathways exist. Power Automate offers automated workflows that eliminate error-prone manual processes, while custom Power Apps provide audit-ready data collection capabilities. Microsoft Dataverse further enhances compliance with comprehensive auditing features that track changes, field modifications, and system access.

The aerospace industry cannot afford to maintain the status quo with legacy systems. Companies that proactively address these IT compliance gaps will not only prevent costly audit failures but also gain competitive advantages through enhanced operational efficiency. Though modernization requires investment, the alternative—continued reliance on systems that fundamentally conflict with AS9100 requirements—represents a far greater risk to aerospace manufacturers in today’s complex regulatory environment.

Audit-proof your aerospace operations. Schedule a consultation with CyberMedics to modernize your IT systems.

FAQs

Q1. What are the main risks of using legacy systems in aerospace IT compliance?

Legacy systems in aerospace IT pose significant risks, including dependency on outdated programming languages, manual process failures in audit documentation, and data visibility issues in reporting systems. These risks can lead to AS9100 audit failures and compromise quality management systems.

Q2. How do legacy systems violate AS9100 requirements?

Legacy systems often violate AS9100 requirements by failing to meet operational risk management standards (Clause 8.1.1), lacking proper traceability capabilities, and being unable to effectively detect non-conformities. These limitations can directly lead to compliance failures during audits.

Q3. What are the security concerns associated with legacy IT systems in aerospace?

Legacy IT systems in aerospace often lack essential security features like multi-factor authentication and encrypted backups. They are also more vulnerable to ransomware attacks and other cyber threats due to unpatched vulnerabilities in unsupported software.

Q4. How can aerospace companies modernize their IT systems to prevent audit failures?

Aerospace companies can modernize their IT systems by implementing tools like Power Automate for workflow automation, custom Power Apps for audit-ready data collection, and Microsoft Dataverse for system integration and compliance. These solutions help automate processes, improve data visibility, and enhance overall audit readiness.

Q5. What are the benefits of modernizing legacy systems for aerospace manufacturers?

Modernizing legacy systems helps aerospace manufacturers prevent costly audit failures, improve operational efficiency, enhance data visibility and traceability, and gain a competitive advantage. It also addresses the talent crisis associated with maintaining outdated systems and improves overall security posture.